LITHUANIAN MUSEUM OF ETHNOCOSMOLOGY

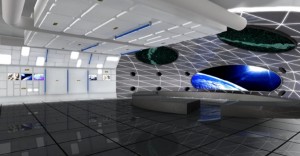

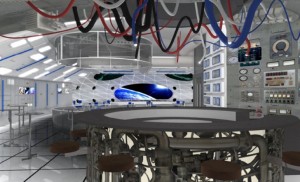

Lithuanian Museum of Ethnocosmology is the unique museum that focuses on the relationship of a man and mankind with the cosmic world. Before the reconstruction of the centre, building operators faced with humidity and temperature problems. They needed an effective solution at minimal cost. The futuristic look of the museum required complex solutions; moreover, ventilation and air-conditioning devices had to be adapted to exclusive futuristic cafe interior designed by architects EKSPO BALTA.

The reconstruction project provided moisture control solution using recirculation and a special control algorithm. The interior has been preserved as the ceiling fan coil units were installed and the ventilation grilles were hidden in niches. Also, a number of energy-saving solutions were applied, and the client was provided with the recommendations for the future reduction of infiltration and the use of natural cooling.

COUNTRY GUEST HOUSE IN KINTAI

There are two major features that exclude newly built country guest house (concept by SPRIK architect study) from others: a custom building layout and hikes in exploitation, as festivals require triple amount of energy compared to duty day. That causes the demand to have engineering systems that are both flexible and capable to adapt to rapid changes.

We simulated the conditions and proposed the concept of the engineering system with the following features:

• Geothermal heat pump is used both to heat and to cool the building

• Solid fuel boiler and geothermal heat pump is connected to one system

• Banquet hall is heated and cooled by air

• Fan coil units are used to condition the guest rooms

SAMOGITIAN MUSEUM “ALKA”

The specifics of the museum are the key challenges of the project: the building itself is the protected object of the cultural heritage, however, the most important is the proper protection of the exhibits that are sensitive to the micro-climate parameters. The uneven traffic of visitors in the exposition halls also makes the impact to the possible solutions.

The specifics of the museum are the key challenges of the project: the building itself is the protected object of the cultural heritage, however, the most important is the proper protection of the exhibits that are sensitive to the micro-climate parameters. The uneven traffic of visitors in the exposition halls also makes the impact to the possible solutions.

The current system does not provide neither the necessary parameters to store museum valuables nor meets the energy efficiency requirements. The building exterior and exhibition halls are disfigured by the openly installed ventilation equipment. The ventilation system is outdated and therefore not in use.

The energy simulation helped to identify major shortcomings in the existing system and to define the requirements for the building structures and the needs for the heat, cold, and moisture in each room. The newly designed system meets the purpose of every room and ensures the normative climate parameters for the exhibits’ storage. Moreover, it significantly improves energy performance consumption. It also gives the possibility to remove the ventilation grilles from the facades. The electrical heating of the air will be replaced by the heat pump and the saved heat from the boiler.

Key elements of the project:

• The heating unit is provided with the balancing valves for the optimal heat distribution;

• The heating capacity, the number of heaters, and the method of temperature control is to be changed in the premises according to the simulation data;

• VRV air conditioning system will be used both for cooling and heating, thus the gas boiler can be turned on later in the fall, and accordingly, turned off earlier in the spring;

• The system for the storage facilities is designed according to the highest regulatory requirements: the separate room has the precision control units installed in technical premises for the elimination of the fire or flooding risk;

• The air flow is provided by the air ventilation units with the heat recovery function, which are installed in the separate technical room;

• The air is distributed through the integrated grilles or air terminals;

• The humidity is controlled by autonomous dryers and humidifiers;

• The centralized building management system (BMS) is used to control the climate, while its web portal monitoring all key parameters and the archive data.

OFFICE BUILDING AND APARTMENTS IN ŽVĖRYNAS

Architect studio SPRIK were challenged to reconstruct the object of the cultural heritage to the office space with the apartments in the attic. The customer preferred to avoid complex internal building insulation, however, his goal was to reach the energy class B. In order to fulfill this requirement, the refrigeration unit (air-to-water) with the heat pump function was designed. This unit gives the possibility to use a more efficient source of energy during the seasons of spring and fall. Two-pipe fan coil units were designed due to the low temperatures heating system instead of usuall radiators . The two-pipe system reduces the costs both of the investment and operating. The energy consumption is also reduced by the efficient rotary heat exchanger in the air conditioning unit that enables the heat recovery from the exhausted air, and the adaptive centralized automatic management system that supports the optimal coolant temperature.

Architect studio SPRIK were challenged to reconstruct the object of the cultural heritage to the office space with the apartments in the attic. The customer preferred to avoid complex internal building insulation, however, his goal was to reach the energy class B. In order to fulfill this requirement, the refrigeration unit (air-to-water) with the heat pump function was designed. This unit gives the possibility to use a more efficient source of energy during the seasons of spring and fall. Two-pipe fan coil units were designed due to the low temperatures heating system instead of usuall radiators . The two-pipe system reduces the costs both of the investment and operating. The energy consumption is also reduced by the efficient rotary heat exchanger in the air conditioning unit that enables the heat recovery from the exhausted air, and the adaptive centralized automatic management system that supports the optimal coolant temperature.

The following solutions were implemented:

• Chiller with a heat pump function is used to heat and cool the building;

• Two-pipe fan coil unit is used for the heating and cooling;

• The gas boiler is combined with the heating system of the heat pump;

• The individual gas boilers are moved from the apartments to a separate room in order to avoid the noises.